Filters and Filter Elements - An Option for Sintered Filters

Sintered filters have been known for a long time and are often used. A wider use of sintered filters is prevented by some major limitations of sintering technology. Porous aluminium filters are an option for sintered filters. Filters and filter elements are manufactured in almost unlimited shapes and dimensions.

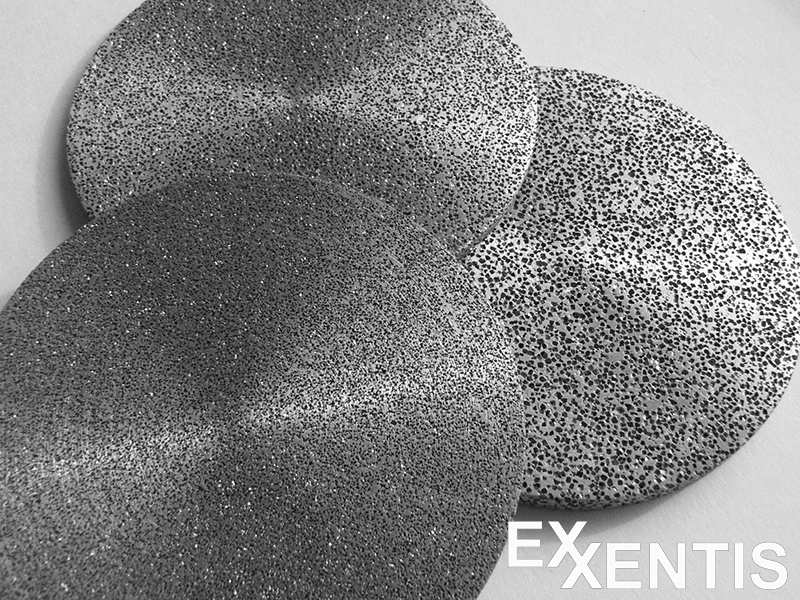

Porous aluminium is produced by casting with salt. This technology gives the porous metal a unique structure. The structure of porous aluminium and the structure of known sintered metals are complementary. The pores in the sintered metal correspond to those in the porous aluminium and vice versa. Theoretically the minimum porosity of sintered metals is 26% and the maximum porosity of porous aluminium is 74%. In reality, 55-65% of porous aluminium consists of pores due to the imperfect stacking of salt particles. Thanks to its high porosity and special pore structure, the porous aluminium filter has a significantly longer service life than the sintered filter.

The highly porous material “porous aluminium” has already found many applications in filtration. Here are just a few application examples:

- gas filters

- oil filters

- air filters

- water filters

- sewage water filter

- chemical filters

- fine dust filter

- liquid filter

- hot gas filter

- hydraulic filter

- cooling water filter

- purifier

Filters and filter elements are manufactured in almost unlimited shapes and dimensions. Filter cartridges, candle filters, filter cartridges, filter plates, filter discs, flat filter elements and flat membranes are well-known and typical applications, but often customer-specific types are also used.

The mounting is usually done with a thread or a flange.

The filters can be easily backwashed, which extends the service life of the filter.

Filters made of porous aluminium can also be used for combined purposes, e.g. as filter silencers. Filter silencers made of porous aluminium reduce the noise level and clean the compressed air when it escapes from pneumatic systems into the atmosphere.

Due to its good thermal conductivity, aluminium is mainly used for heat transfer. This property can also be combined with the structure of the porous aluminium and at the same time use filters as heat exchangers.