Heat exchanger

Porous aluminium heat exchanger

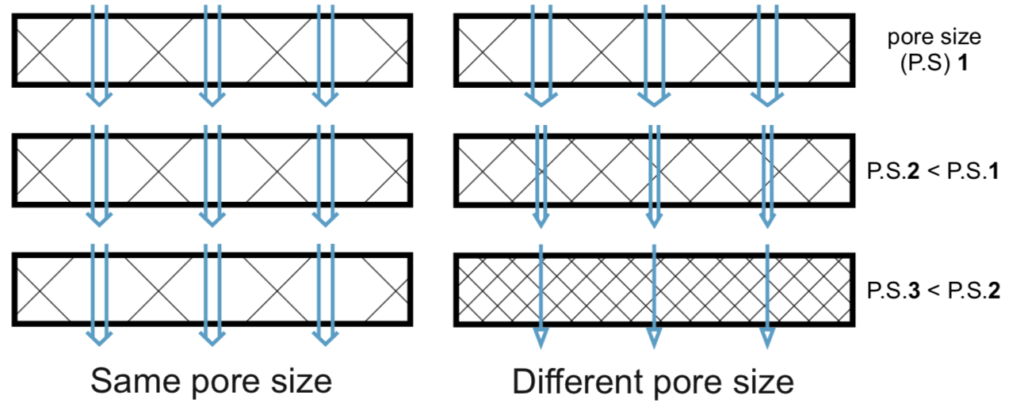

Porous aluminium is ideal for use as a heat exchanger. Due to its good thermal conductivity, aluminium is mainly used for heat transfer. The heat exchange capacity of porous aluminium is higher than that of conventionally processed aluminium, as porous aluminium has a very large internal surface area in relation to its volume.

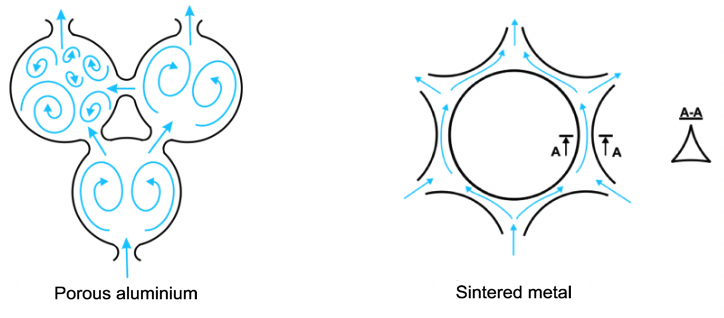

However, large surfaces also have other porous materials, e.g. sintered metals. Today, however, it is not yet possible to manufacture products from aluminium with high volume porosity and sufficient strength using sintering technology. Another advantage of porous aluminium is its cast structure, which also promotes thermal conductivity. In the case of sintered metals, a thermal resistance develops at the contact points of the pressed balls.

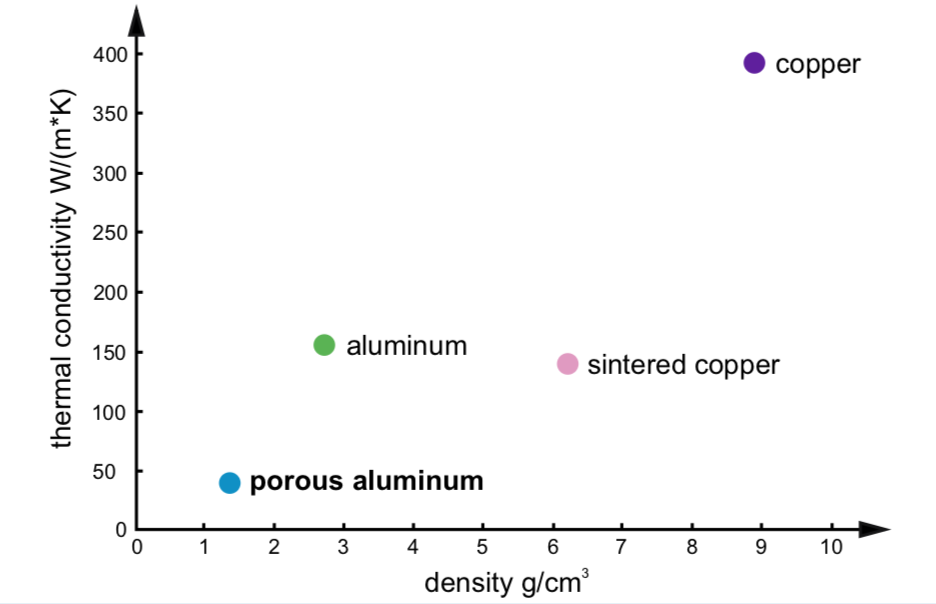

The thermal conductivity of porous aluminium has been tested at the Technical University Bergakademie Freiberg: depending on the pore size, the thermal conductivity of the material is in the range 30 – 50 W/(m*K). Products made of porous aluminium can therefore be used very well for heat transfer.

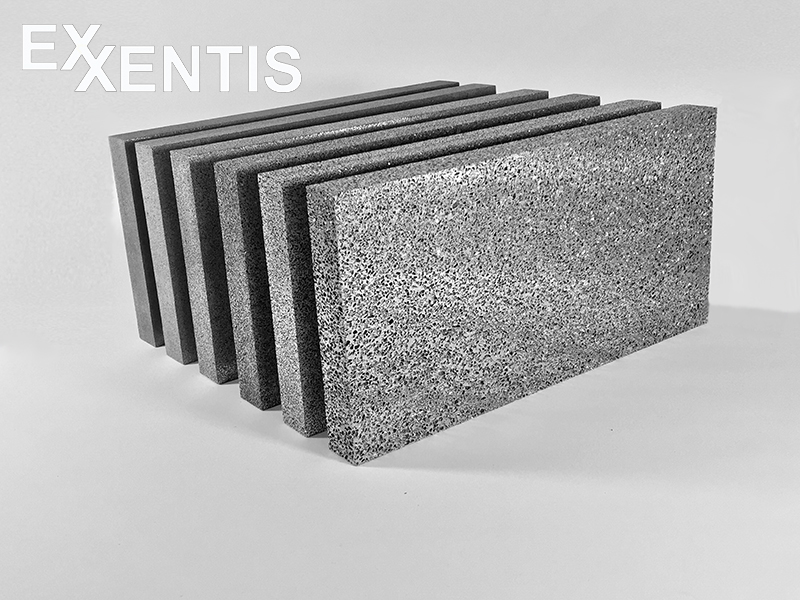

Due to the high volume porosity and the large inner surface, they are also suitable as heat exchangers in convective heat transfer. Water or other liquids, air or gas flow through the porous aluminium, which optimally absorbs the temperature through its large inner surface. This temperature can be transferred to a solid or to a fluid in the same way.

Porous aluminium is also ideal for cooling. The obiekt to be cooled is attached directly to the porous aluminium and the heat is optimally dissipated to the outside air by the large inner surface, if necessary with ventilation.

Due to its high thermal capacity and thermal conductivity, aluminium is often used in various thermal processes. Porous aluminum offers additional advantages to create efficient heat exchangers. Especially in industries where low material weight is important:

- automotive industry, including electric vehicles

- aircraft industry

- aerospace industry

Heat capacity and thermal conductivity

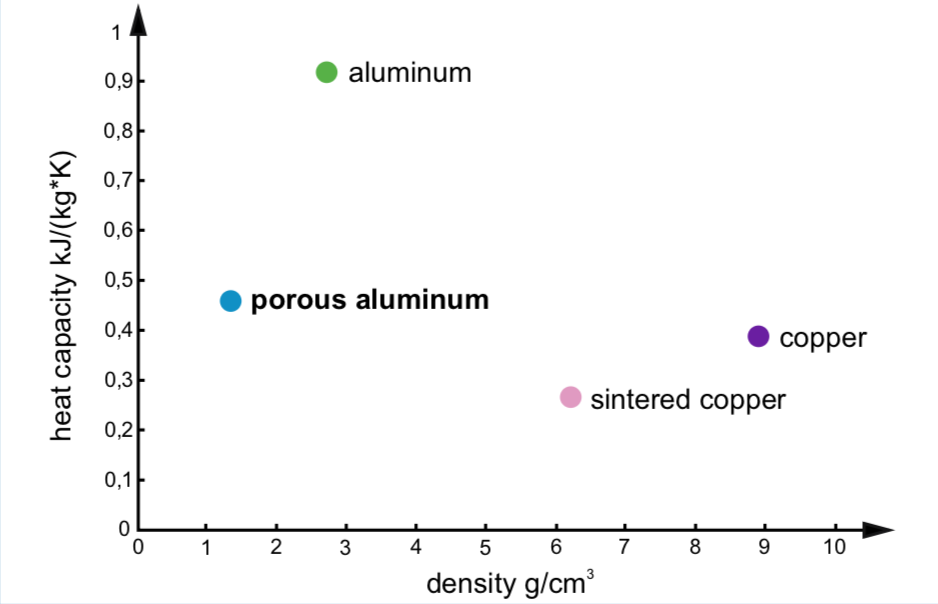

Heat absorption due to the high heat capacity of aluminium: the larger the aluminium mass, the more heat it can absorb during heating.

Heat dissipation thanks to high thermal conductivity: The larger the temperature gradient and the larger the cross-section of the product, the more intense the heat flow through the porous aluminium.

Heat transfer due to the high specific surface area of porous aluminium: The larger the specific surface area, the more intense is the heat transfer of the liquid or gaseous medium flowing through porous aluminium.

Heat capacity: (porous) aluminium and (sintered) copper

Thermal conductivity: (porous) aluminium and (sintered) copper

Advantages of the pore structure

1. Large contact area between gas and porous aluminium matrix

| Nr.1 | Nr.2 | Nr.3 | Nr.4 | Nr.5 | Nr.6 | Nr.7 | |

| Pore size mm | 0.20 – 0.35 | 0.30 – 0.50 | 0.40 – 0.63 | 0.40 – 1.00 | 0.63 – 1.60 | 0.63 – 3.00 | 0.63 – 4.00 |

| Surface m2/m3 | ca. 20’000 | ca. 10’000 | ca. 6’500 | ca. 4’000 | ca. 3’000 | ca. 2’500 | ca. 2’200 |

2. A long contact time between the gas and the porous aluminium matrix. Gas flows follow complex paths with vortices.

The great advantage of porous aluminium for the production of efficient heat exchangers is its permeability to liquids and gases. When liquid or gas flows through a block of porous aluminum, it receives or emits thermal energy due to a large contact surface with the aluminum surface.

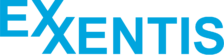

Thanks to a wide range of available pore sizes, it is possible to precisely control heat absorption and heat transfer processes in porous aluminum, including by organizing a multi-stage process:

Porous aluminum is an effective material for solving such tasks as:

- Cooling, heating, evaporation of liquids

- Heating, cooling and condensation of gases and vapours