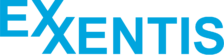

Comparison with metal foam

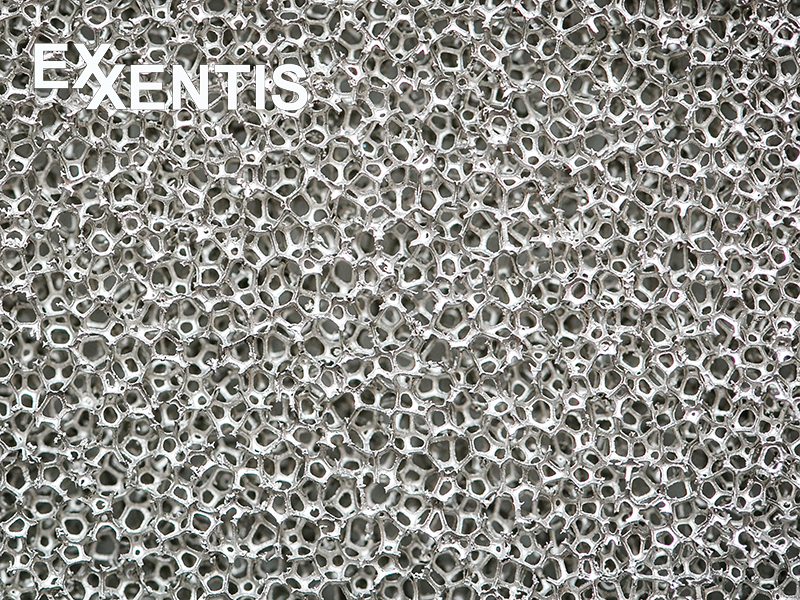

Open-cell metal foam and porous aluminium are both permeable to gaseous and liquid media, but differ in manufacturing technology and properties. Aluminium is poured together with crystal salt, then the salt is washed out and the pores take the place of the salt grains and their contact points to form porous cast aluminium.

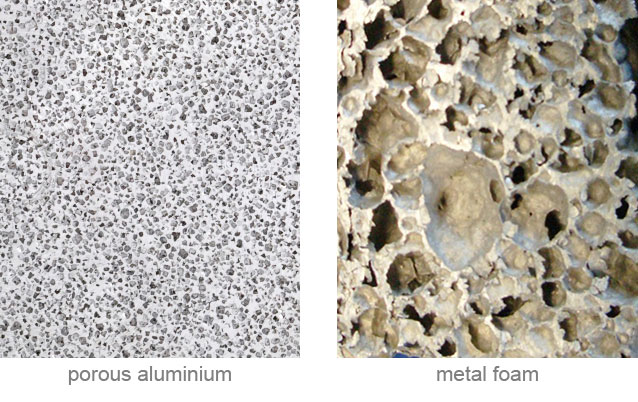

Thanks to their high breaking strength and low weight, foamed metals are becoming increasingly important as industrial materials. Above all as lightweight components in vehicle construction, but also in heating technology, thanks to their large inner surface and good thermal conductivity. Metal foams are usually made of aluminium or aluminium alloys although it is possible to foam copper, zinc or lead.

Metal foam manufacturing technologies

Metal powder or metal chips are mixed with titanium dihydride or other propellants and heated above the melting point of the metal. This releases gaseous hydrogen, which foams the mixture.

Gas is blown into molten metal and after cooling the porous structure remains.

Difficulties in the production of metal foams are mainly to find the right combination of metal and blowing agent and to heat them up to the correct temperature in the right period of time. This is the only way to achieve the desired result. The control of the pore proportions, pore size and also the distribution of the pores is practically unpredictable.

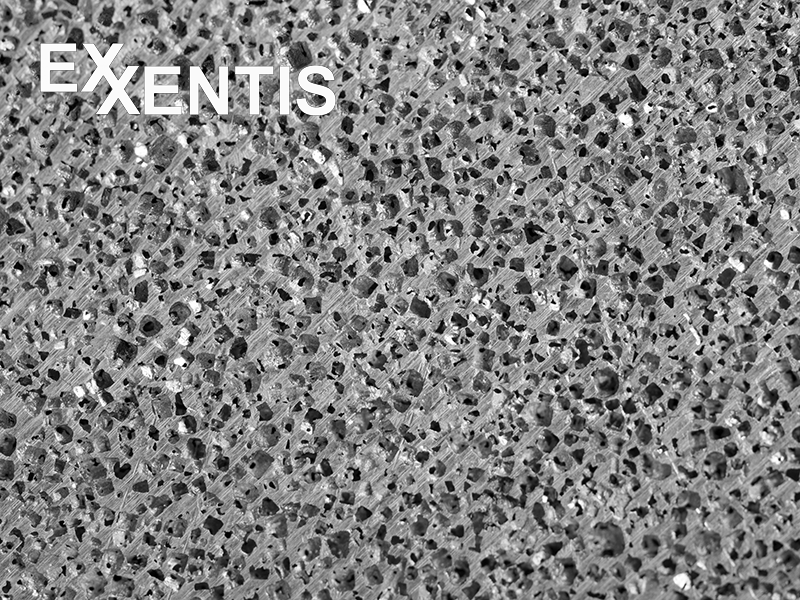

For these reasons, porous, cast aluminium with its simple manufacturing technology is a valuable alternative. The broad spectrum of precisely defined pore sizes from 0.2 mm to 4.0 mm makes it possible to produce the optimum porosity for the desired application. The inseparable connection of porous and non-porous parts opens up a wide range of applications in the simplest way.

*Porous aluminium is an open-pored metal foam obtained by casting with salt.

Porous aluminium has the following main advantages over metal foam:

- Volume porosity control

- Pore size control

- Control of pore distribution / homogeneous structure

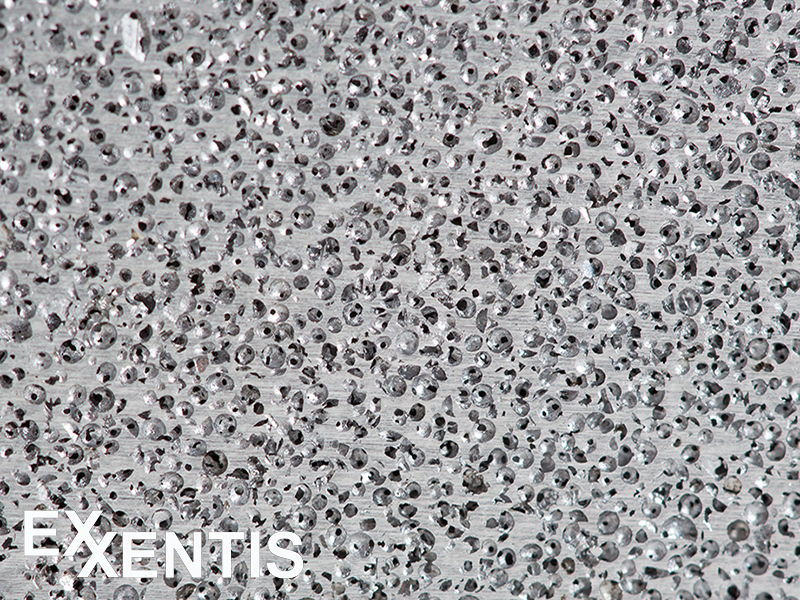

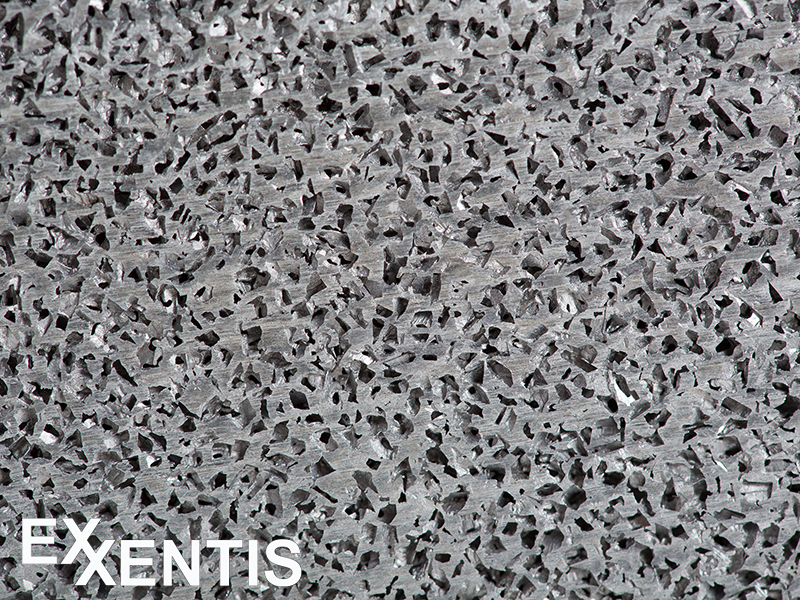

Two types of salt are used in the production of porous aluminium. It is a salt with particles of a spherical shape and a splinter shape:

Porous aluminium has a unique combination of material properties. Thanks to the unique combination of material properties, porous aluminium is ideal for many applications.