Manufacturer of zirconium, hafnium, niobium, tantalum, calcium

Since 2019 Exxentis is a representative of the manufacturer of zirconium, calcium, hafnium, niobium and tantalum.

Quality control

- Quality control of every production step – from raw material to end product

- The technical control department and the central laboratory are two large special units for the quality control of the final products with all the necessary modern quality control equipment.

- Successful external audits of the Zirconium Product Quality Management System by ABB Atom AB (Sweden), Fortum Engineering Ltd. (Finland), NU-TECH Precision Metals Inc. (Canada), AECL (Canada), ČEZ, a.s. (Czech Republic), Slovenské Elektrárne (Slovakia), Paks NPP (Hungary), KNF (Korea), GNF (USA), etc.

- 70 years of successful supply to the nuclear industry, one of the most demanding in terms of product quality

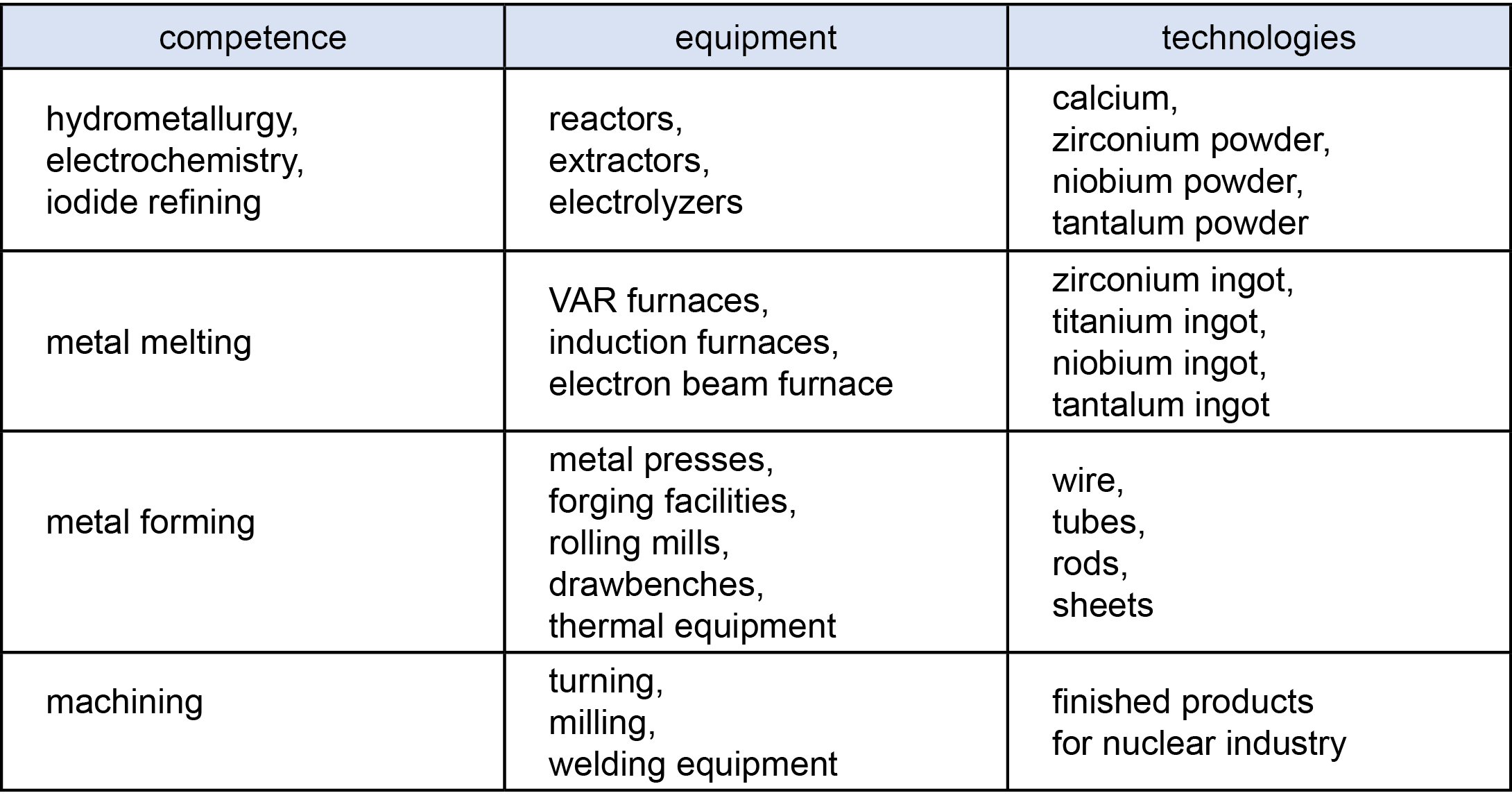

Unique combination of production possibilities

Some production possibilities

1. Forged products with round, square and rectangular cross-sections, with a maximum length of 10’000 mm

2. Forged products with round cross-sections in length max. 25’000 mm

3. Forged tubes and rods: Ø tube / rod min. 10 mm; tube wall thickness min. 5 mm; length max 6’000 mm

4. Bars, cold-rolled: Ø 7 – 25 mm; length max. 7’000 mm

5. Wire, cold rolled: Ø 0,45 – 7 mm

6. Seamless cold-rolled tubes:

- Ø 6-16 mm; wall thickness 0.1-1.6 mm; length 1,500 – 5,000 mm

- Ø 9-18 mm; wall thickness 0.2-2.3 mm; length 1’500 – 5’000 mm

- Ø 15-30 mm; wall thickness 0.1-2 mm; length 1’500 – 4’000 mm

- Ø 33-17 mm; wall thickness 0.4-2.2 mm; length 1’500 – 4’000 mm

7. Pipe belt grinding with length max. 7’500 mm

8. Centerless pipe grinding with a length of max. 9’500 mm

9. Pipe honing with length max. 10’000 mm

10. Pipe sand blasting with a length of max. 10’000 mm