Aluminium foam - overview - types - production - applications

Aluminium foam (the porous metal based on aluminium and its alloys) has been known for more than half a century, but still has a relatively small distribution and application. The main reason for this was the low reproducibility of structure and material properties in the production of aluminium foams. The development of aluminium foam technology has made it possible to overcome some of these difficulties. Various processes for the production of metal foams have been developed and investigated.

Originally, the inventors of such materials were inspired by natural porous materials such as wood, bone, coral, pumice and some other porous minerals. The common feature of these materials is the combination of high strength, low specific weight and good energy absorption. Nowadays, manufacturers of aluminum foams can produce metals with similar properties relatively easily. The range of applications of aluminium foams is now much wider and has dozens of different applications.

Types of aluminium foams

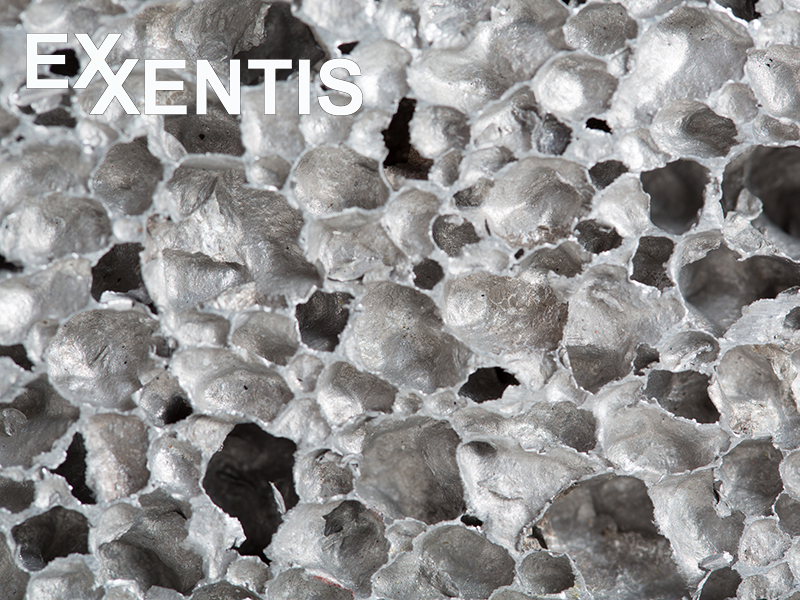

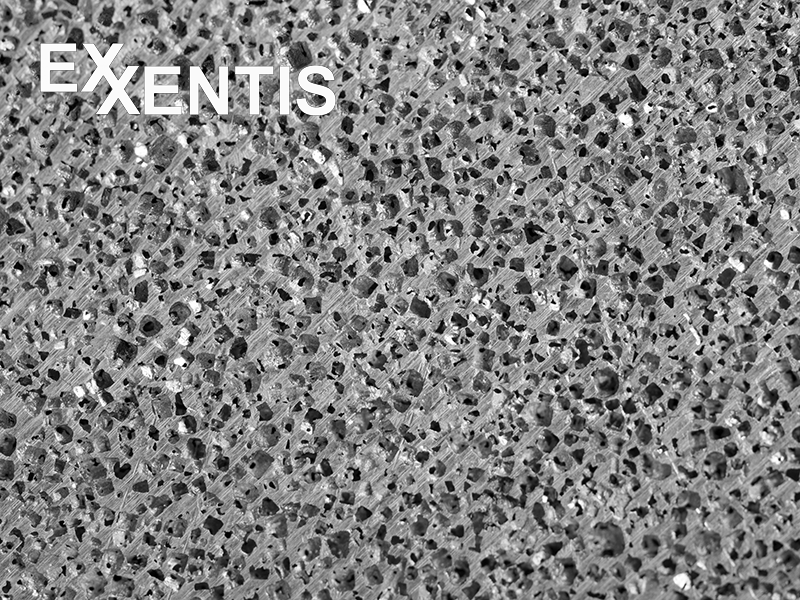

Porous metals have open or closed pores depending on the manufacturing technology. In the first case such materials are called cellular metals, in the second case they are called metal foam. Within each of these groups there are variations which ultimately result in a wide class of aluminium foams with different properties.

Production of aluminium foam

There are different processes for the production of aluminium foams.

In one case, the metal foam is obtained from the molten metal in different ways. As the aluminium cools and hardens, the metal foam stabilises. Gas streams or blowing agents are used to form the foam. Blowing agent decomposes under certain conditions and results in gas emissions. Special additives are sometimes used to stabilize the gas bubbles so that the foam does not disintegrate before curing. This process can be used to obtain aluminium foam sheets, products with simple shapes and aluminium foam sandwiches. Such products have metal foam as the core, which is covered on both sides with a layer of solid aluminium.

Another method is casting with a filler. For example, salt grains can act as fillers, which are then washed out of the aluminium matrix, and pores appear instead of salt particles. Polyurethane foam with a temperature-resistant coating is also used as a filling material, which burns out during heat treatment.

Another production process of aluminium foam uses hollow ceramic or metal balls, which are inserted into the metal matrix.

In injection moulding, polymer granules can be used to create pores. Due to the very short process time, these granules do not decompose under the influence of high temperatures. They either remain in the metal matrix as fillers or are removed by prolonged heat treatment. In the latter case, an open-pored aluminium foam is obtained.

The production of metal foams still has one direction, powder metallurgy. First, a mixture of aluminium powder with special additives is produced. When such a mixture is heated, foam and sintering processes occur which, after cooling, result in further types of aluminium foam.

The most modern way to obtain porous metals is additive technology. With additive manufacturing, the shape and 3D structure of the component can be controlled very precisely. However, this process is still very cost-intensive and can only be applied to a limited number of metals.

Properties and applications

Closed-pore aluminium foam has a porosity of 80 to 98%. Its strength significantly exceeds that of a solid metal of the same weight. The use of such materials has great potential, especially for the means of transport of the automotive industry, the aerospace industry and shipbuilding. The weight reduction leads to fuel savings or makes it possible to increase the weight of the load to be transported.

The porous structure of the aluminium foam absorbs the impact energy. This property can be used during transport to protect against collisions, as armor and explosion protection. Metal foam dampens sound. Therefore, aluminium foam panels can be used as sound absorption walls along streets and railways. Sound insulation of cinemas and concert halls can also be effective. Due to its low weight and beautiful surface, aluminium foam is used for interior and exterior design.

Open-pore aluminium foam is permeable to gases and liquids, has low weight and high structural strength. Permeability significantly increases the use of aluminium foam. Such materials are used to filter gases and liquids, to reduce the noise of pneumatic devices, as forming tools for the production of EPP/EPS products, for vacuum tables, for various heat exchangers, etc.

Porous aluminium is a type of open-pore aluminium foam. On our website you will find more information about our technology, properties and applications of porous aluminium. Thanks to the high flexibility and adaptability of the technology, porous aluminium can successfully compete with many porous materials in many applications. In most cases, porous aluminium replaces sintered metals, porous ceramics, porous plastics, nets and wire materials.