Comparison with other porous materials

The production technology of porous aluminium differs from that of other porous materials. Thanks to the high flexibility and adaptability of the technology, porous aluminium can successfully compete with other porous materials for various applications. In most cases, porous aluminium is a valuable alternative to sintered metals, porous ceramics, porous plastics, nets and wire materials.

Porous aluminium instead of felt silencer

Before the introduction of silencers made of porous aluminium, multi-part silencers with felt were used. For each silencer, the thickness of the felt was individually selected and several tests were carried out to obtain the required silencer parameters.

The use of porous aluminium silencers made it possible to remove much of this manual work. The properties of porous aluminium silencers are well reproduced by observing precise technological parameters.

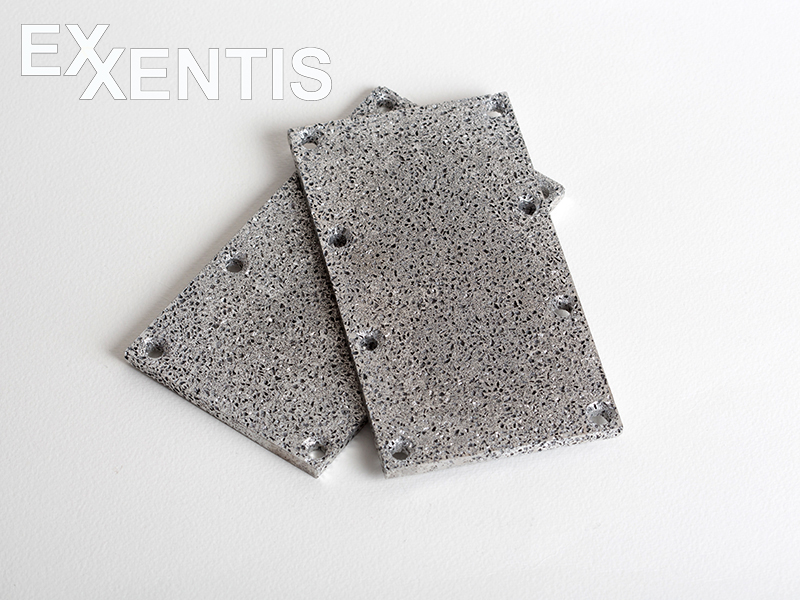

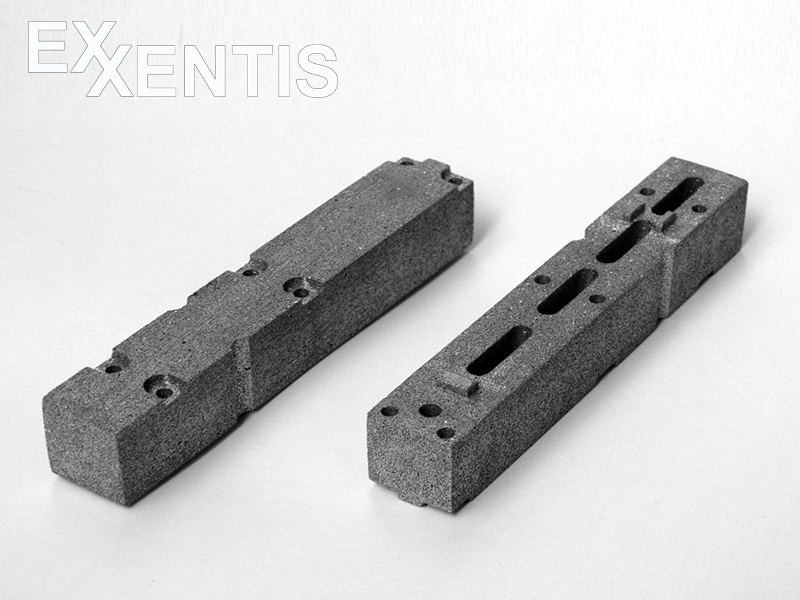

Porous aluminium instead of sintered plate silencer

Sintered bronze silencers require the use of 2 parts to achieve the required noise reduction. Such plates are often destroyed by constant vibration and shock loads. Steel cover plates with slots have been used to extend the life of sintered bronze plates. However, this reduced the surface area and efficiency of the silencers. With porous aluminum, you can immediately adjust the desired thickness and thickness. These silencers have smaller back pressure, larger working area, longer life, are vibration and shock resistant.

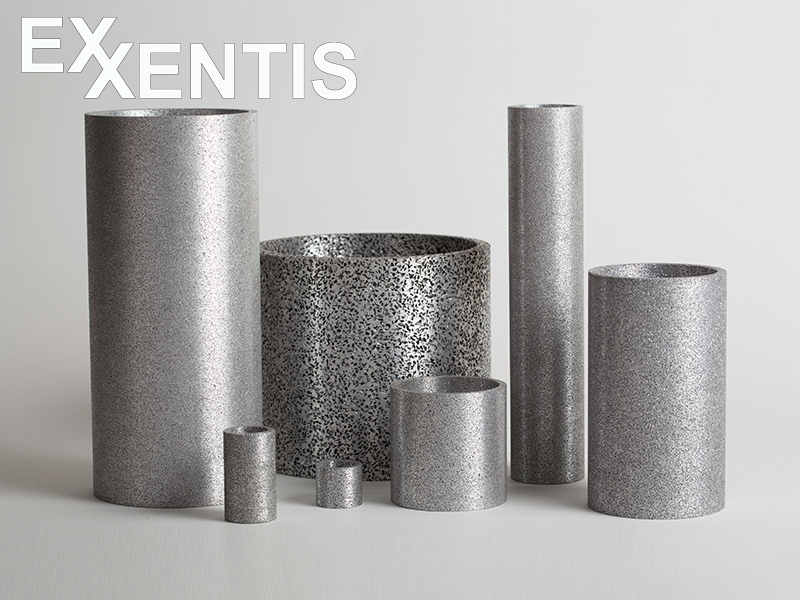

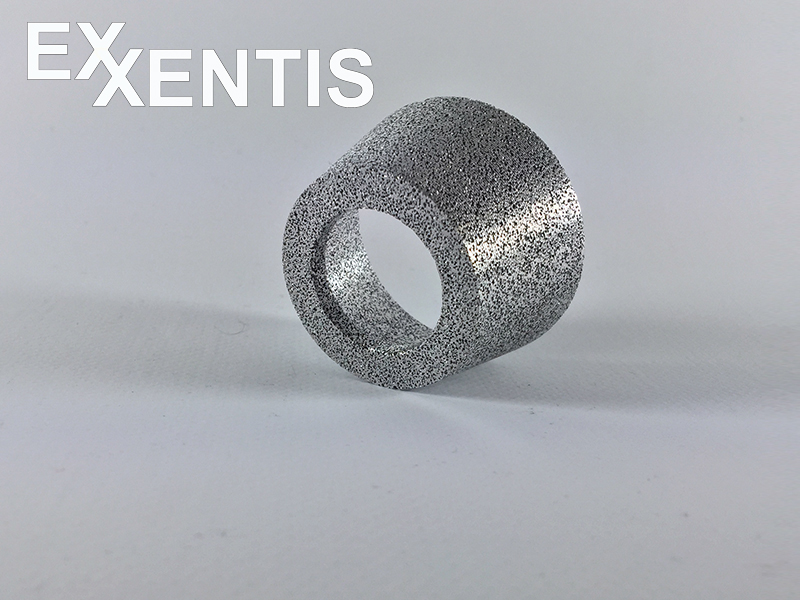

Porous aluminium instead of sintered threaded silencer

Standard sintered bronze silencers have a sufficient sound level – reduction, but their shape and size are severely limited by the sintering technology. Silencers made of porous aluminium can be manufactured in various shapes and sizes for your individual task. For the production of products made of porous aluminium, no cost-intensive press moulds are required, as is the case with sintering technology, but conventional casting moulds – chill moulds. The innovative and relatively simple production technology allows us to offer a favourable price-performance ratio even for small quantities.

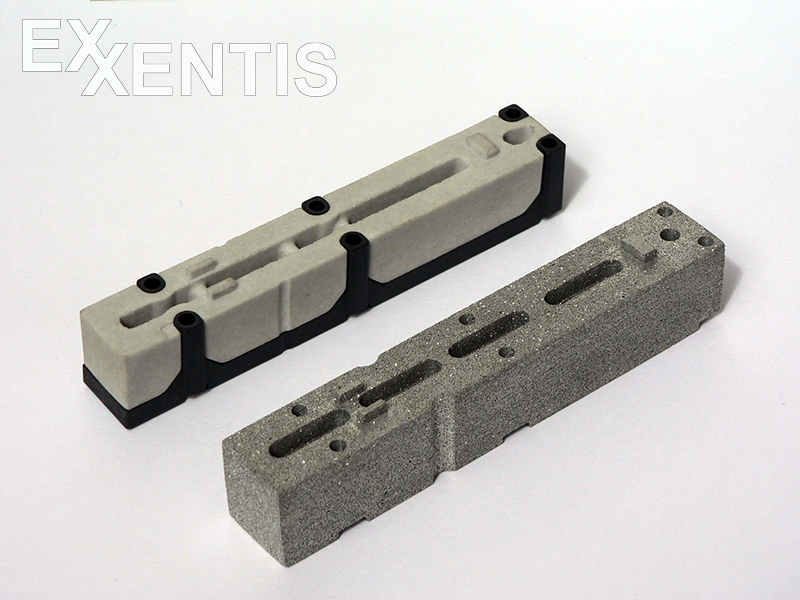

Porous aluminium instead of porous ceramics

In order for ceramic filters to have a sufficient service life, they must be manufactured with a large wall thickness. They are therefore heavy but still fragile and require careful handling. Filters made of porous aluminium have a 5-10 times smaller wall thickness, 7-15 times lower weight and at the same time have a higher strength, are vibration and shock resistant. A higher working pressure when using porous aluminium allows better cleaning of the filters in filtration regeneration cycles, which more than doubles the life of the filters.

Porous aluminium instead of porous plastic

Porous aluminium instead of pressed wire

Filters made of pressed wire have the special feature of deforming and gradually changing their shape when subjected to high pressure. After the pressure is removed, the filter shape is not restored to its original shape. This affects the stability of the filter properties and shortens the life of the filters. Porous aluminum filters have a solid and durable shape and stable properties throughout their life. The rigidity of porous aluminum allows you to obtain shapes and sizes that are not available for pressed wire filters.