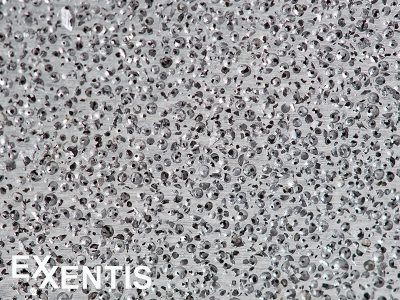

Applications - open-pore aluminium foam

Thanks to the unique combination of material properties, porous aluminium (open-pore aluminium foam) is used in many industrial applications. Solid aluminium and its alloys are one of the most widely used materials today. Porous aluminium, like ordinary solid aluminium, has such properties as good thermal conductivity and high thermal capacity. In addition there are the permeability, high specific surface and the low weight. This combination opens up a wide range of applications for porous aluminium.

Advantages of porous aluminium

- permeable over the entire volume, all pores are open

- any shape and size according to customer requirements

- 7 standard types of pore sizes

- high strength thanks to cast structure

- low weight thanks to 60% volume porosity

- homogeneous distribution of pores over the entire volume

- high thermal conductivity and heat capacity

- the production technology is innovative and relatively simple, fundamentally different from the production technologies of sintered metals and metal foams

Applications of open-pore aluminium foam

| Bulk material / powder | Liquids | Facilities | Gas / steam | |

| Compressed air | Pneumatic transport, aeration, fluidization | Aeration | Filtration, silencing, acoustic insulation | |

| Vacuum | Bulk material compaction, volume reduction | Vacuum tables | ||

| Thermal energy | Heating, cooling or drying in a fluidized bed | Heating, evaporation, cooling | Thermoforming, heat exchangers | Gas and steam condensation |

| Steam | EPS / EPP foaming tools | Filters and filter elements, silencing | ||

| Facilities | Filtration | Lightweight material | Filtration, silencing, even gas distribution, cooling and protective housing for sensors | |

| Other applications | Energy absorption and damping, vibration dampers, explosion protection | Flame arrestors | Weapon sound suppressors | Design and decor |

Porous aluminium has a high porosity (pore volume / total volume) of about 55-65% and a homogeneous pore distribution. The pores are open and the material is completely permeable. Porous aluminium with small to medium pores is successfully used for vacuum generation, in the form of vacuum tables or vacuum plates. The homogeneous pore distribution ensures full-surface suction. The permeability can be adjusted very precisely thanks to the possibility of selecting plates in different thicknesses and pore sizes.

Products in any shape can be made from porous aluminium. This results in complex vacuum moulds for thermoforming or tool moulds for the production of foam mouldings from EPP (expandable polypropylene) or EPS (expandable polystyrene).

Porous aluminium has a high specific surface and is completely permeable. The combination of these properties also makes porous aluminium very attractive for the production of new generation heat exchangers.

Thanks to its open cell structure and high specific surface area, porous aluminium is also a material with very good sound insulating properties. Pneumatic silencers will be manufactured according to individual customer requirements. Compressed air silencers made of porous aluminum is a valuable alternative to silencers made of sintered metals, ensuring an effective noise reduction of pneumatic systems. Our silencers have an extra strong cast connection between porous aluminium and solid aluminium areas. The all-aluminium part often appears as a thread, flange or other fastening element.

Porous aluminium products are also used as weapon silencers. The combination of good thermal conductivity and high dirt-holding capacity is crucial for this application. The open pore structure ensures permeability and high volume porosity and thus a very high insulation performance.

Filters and filter elements made of porous aluminium have a higher volume porosity than sintered filter elements. The particularly important difference between porous aluminium and sintered metals lies in the pore structure. The pore structure of these porous materials is reversed. The pores of sintered metals are channels between the metal spheres. In porous aluminium, the channels between the salt particles and later between the pores are filled with aluminium. The pores of porous aluminium have more space, volume and therefore a much higher dirt capacity than sintered metals.

Porous aluminium can be used in many different applications. Do not hesitate to contact us. We will be happy to advise you and work out an optimal solution tailored to your requirements.