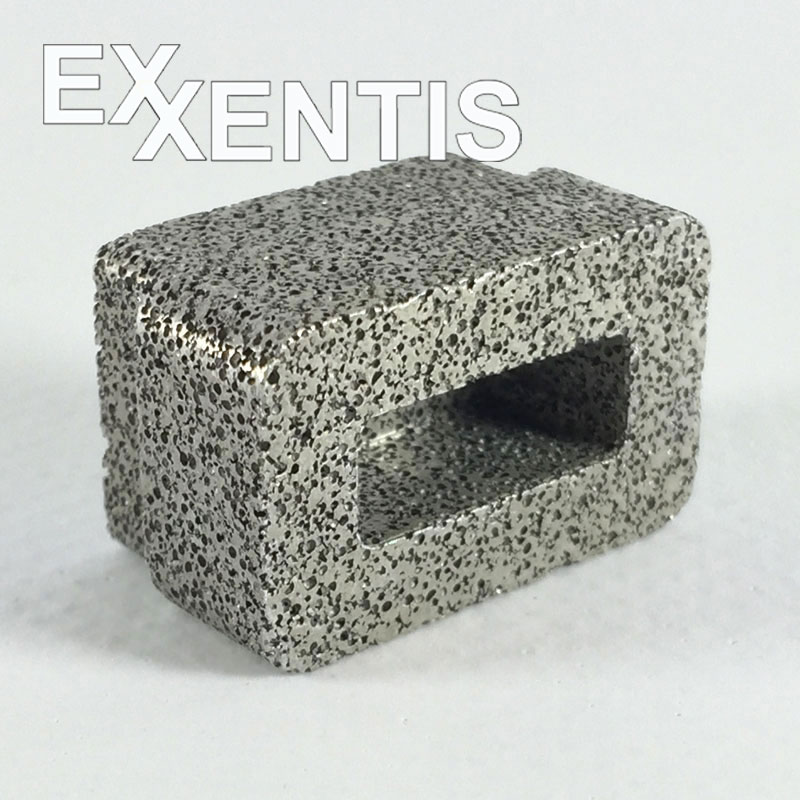

Comparison with sintered metal

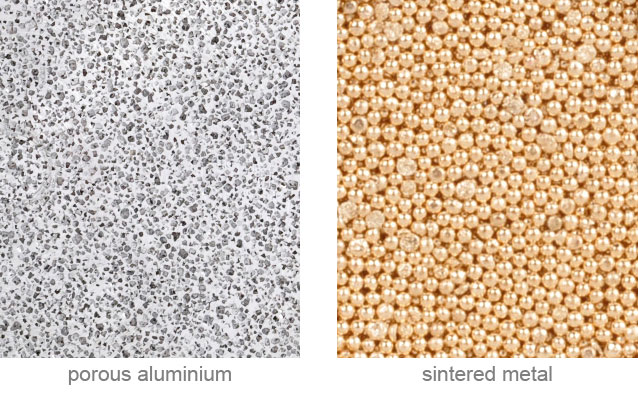

Porous aluminium and sintered metal are both open-cell and therefore permeable, but the production technologies and thus also the structure of the materials differ. In the production of porous aluminium, liquid aluminium is poured together with crystal salt. After cooling and mechanical processing, the salt is washed out. The pores replace the salt grains and their contact points. In the case of sintered metals, metal grains are baked together. In this case, the empty spaces between the grains become the pores. So it is just the other way round. In the case of porous aluminium, the pores form instead of the salt grains and the voids in the granular salt are filled with metal.

Porous metals play an important role in modern technology. Filters and filter elements, trunnion bearings, silencers, fire barriers etc. are made of various metal powders according to the powder metallurgy method (powder metallurgy materials), so-called sintering technology (sintered metal).

If permeable materials with high stability and high volume porosity are required according to the sintering method, bronze, copper or steel are usually used. Due to its low density, good corrosion resistance and comparatively high thermal and electrical conductivity, aluminium has many advantages over bronze, steel and copper. However, it is difficult to produce porous materials from aluminium using sintering technology.

The following difficulties arise in the production of sintered aluminium: aluminium powder reacts quickly and the aluminium grains oxidise to the non-fusible oxide Al2O3. The temperature at which the oxide coating would dissolve is much higher than the melting temperature of the aluminium. This temperature also depends on the size of the aluminium grains and the thickness of the oxide layer. Theoretically there are some approaches to solve this problem, but in practice it has not yet been realized to manufacture products from aluminium with high volume porosity and sufficient strength according to sintering technology. Now we offer a solution – porous aluminium.

Advantages over sintered metal:

Sintered aluminium cannot be produced today

Volume porosity of porous aluminium can be approx. 55-65% high. Volume porosity of sintered metals is approx. 30-35%.

Thanks to its cast structure, porous aluminium has high stability and does not crumble, unlike sintered metals.