Vacuum plates made of porous aluminium for vacuum tables and vacuum clamping systems

Vacuum tables

Vacuum tables are used for fast clamping and releasing of the workpiece. They are also used for processing thin and flexible materials that are difficult or impossible to fix in other ways.

The main types of vacuum tables:

- with perforated plates

- with grooves

- with porous plates

The vacuum table holds the workpieces in the vacuum chamber of the vacuum table due to the difference between atmospheric pressure and pressure. The clamping force on the vacuum clamping table depends on the sum of the areas of the holes in the vacuum plate below the surface of the workpiece and on the pressure difference that the vacuum pump can generate.

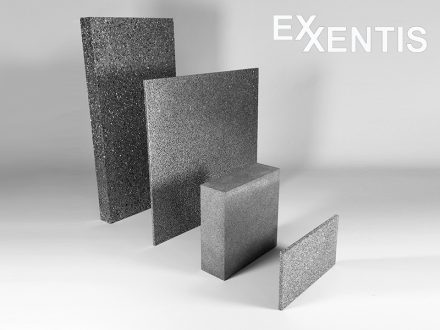

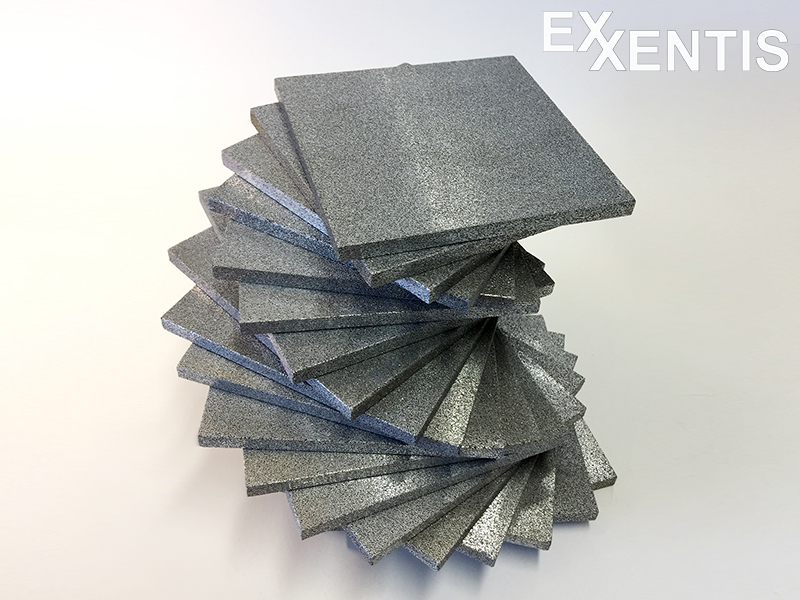

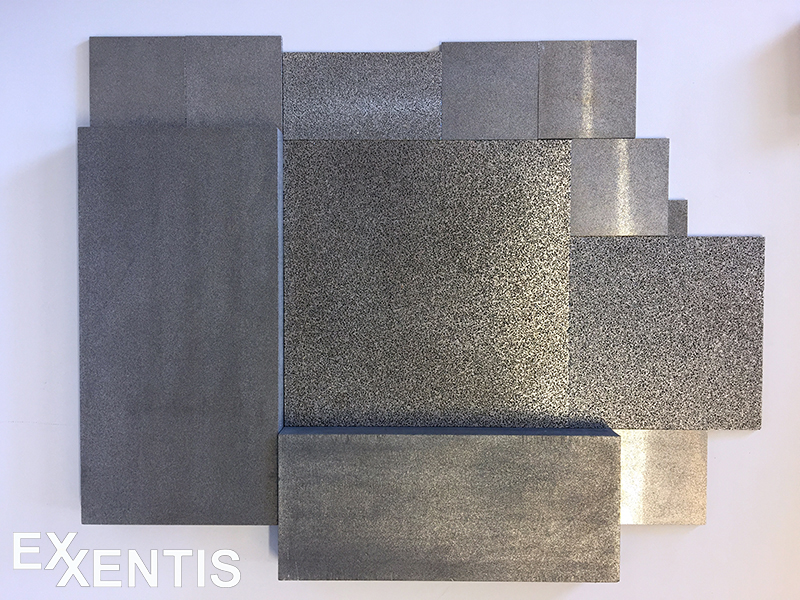

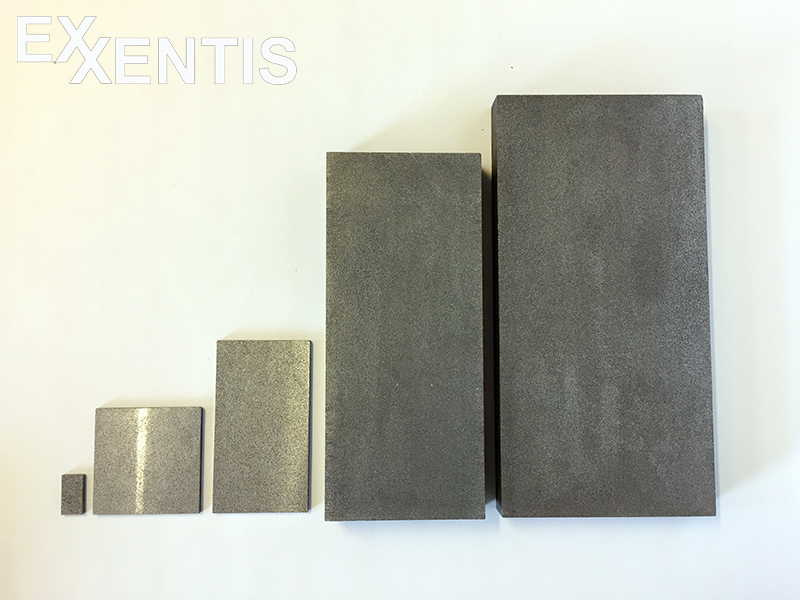

Porous aluminium vacuum plates

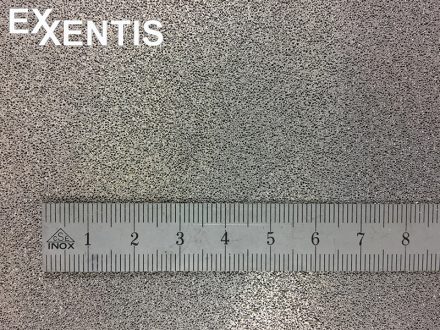

In porous aluminum plates for vacuum tables, pores occupy 55-65% of the surface area at any point of the vacuum plate and on any small area.

This is achieved due to the small pore size and even distribution of pores on the surface of porous aluminum.

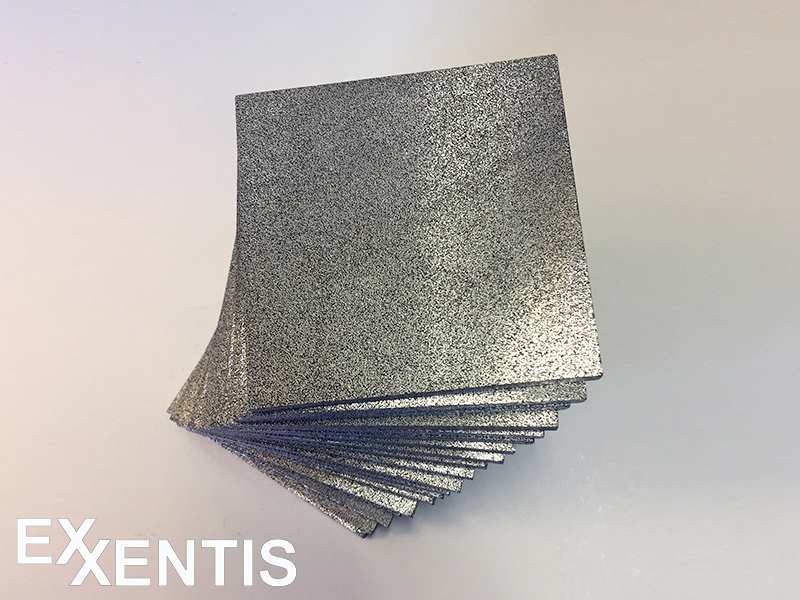

These properties of porous aluminum provide maximum clamping force and allow you to place the workpiece anywhere and in any position on the vacuum table.

Thanks to the possibility of varying the pore sizes and the thickness of the vacuum plate, you can set exactly the time necessary to adjust the clamping force.

Vacuum tables with vacuum plates made of porous aluminum are suitable for metalworking, woodworking, plastics processing, paper processing, film processing and much more.