Structure of porous aluminum

Have you ever seen such a structure of porous metal?

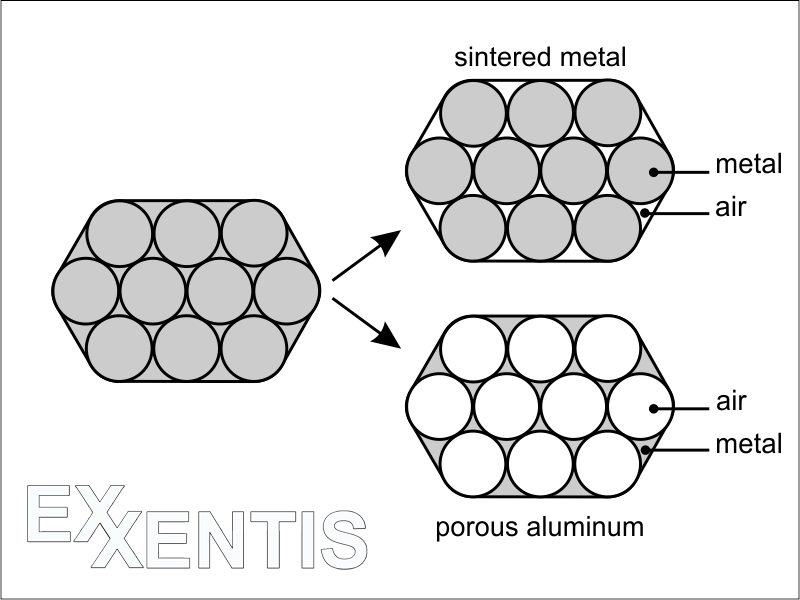

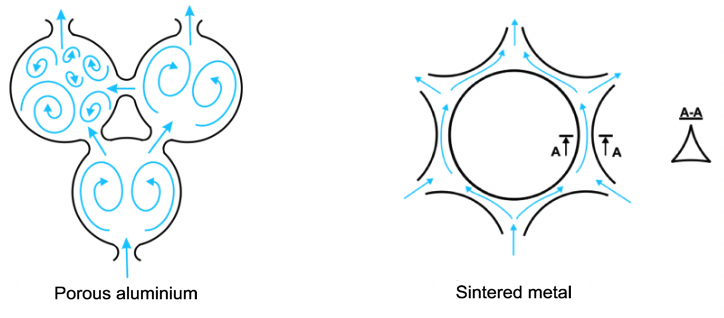

Comparison of the structure of porous aluminium and sintered metals

Porous aluminium is produced by casting with salt. This technology offers a unique structure of porous metal. The structure of porous aluminum and the structure of known sintered metals are complementary.

The pores in the sintered metal correspond to those in the porous aluminium and vice versa. Theoretically, the minimum porosity of sintered metals is 26% and the maximum porosity of porous aluminium is 74%. In practice, 55-60% of porous aluminium consists of pores due to the imperfect stacking of salt particles.

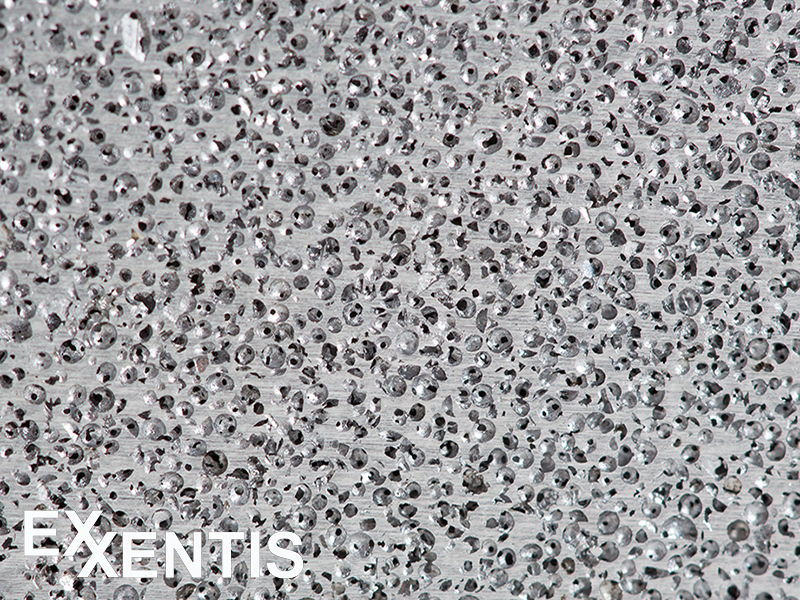

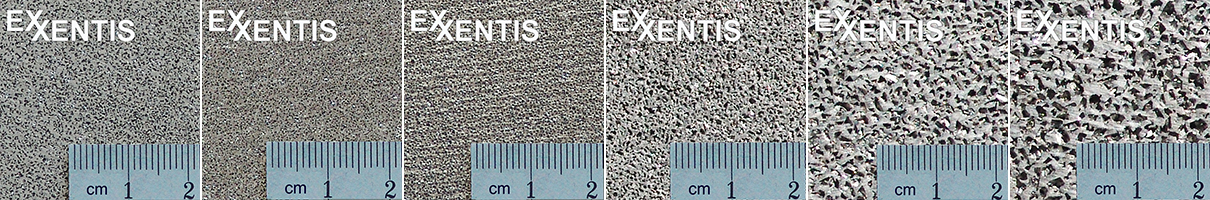

Shape and size of pores

The properties of porous aluminium depend very much on the size of the pores. We use 6 different salt fractions to obtain porous material with very different properties. This allows us to produce the optimal product for each customer.

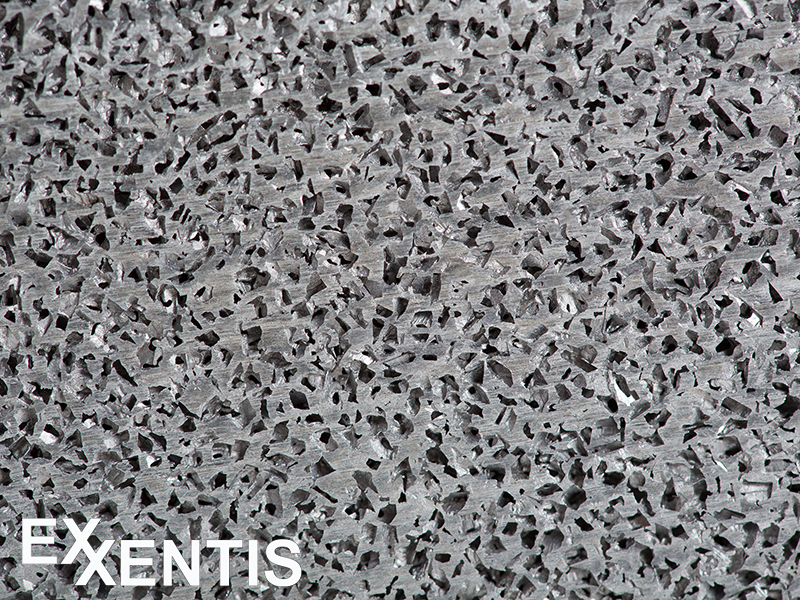

Connection between the pores

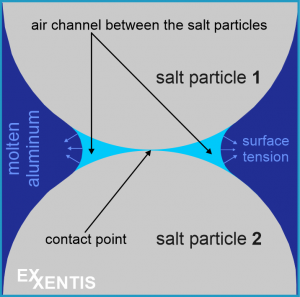

In the production of porous aluminium, each salt particle has many contacts with other salt particles. The surface tension prevents molten aluminum from reaching the contact point between two salt particles. Therefore, first all salt particles and then all pores are bonded together. All pores are open, so porous aluminium is permeable over its entire volume and in all directions.