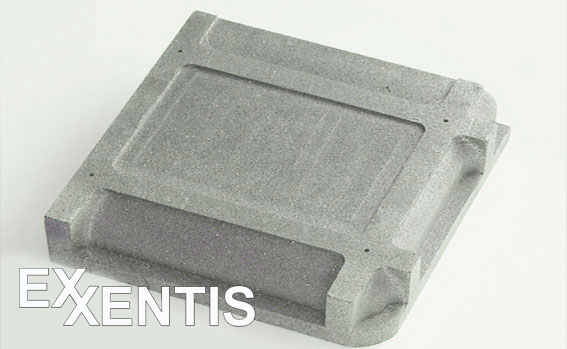

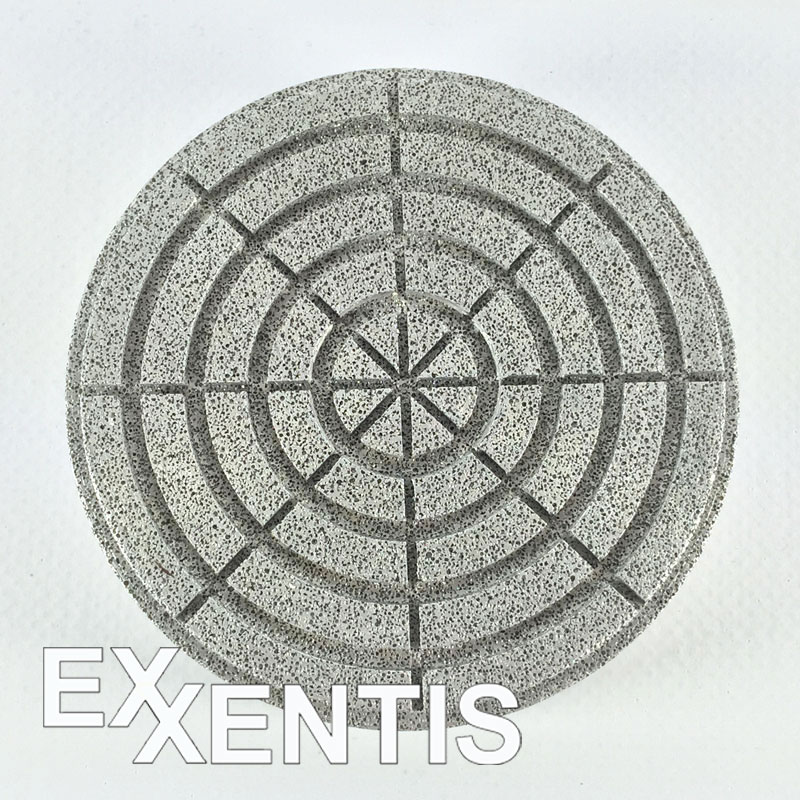

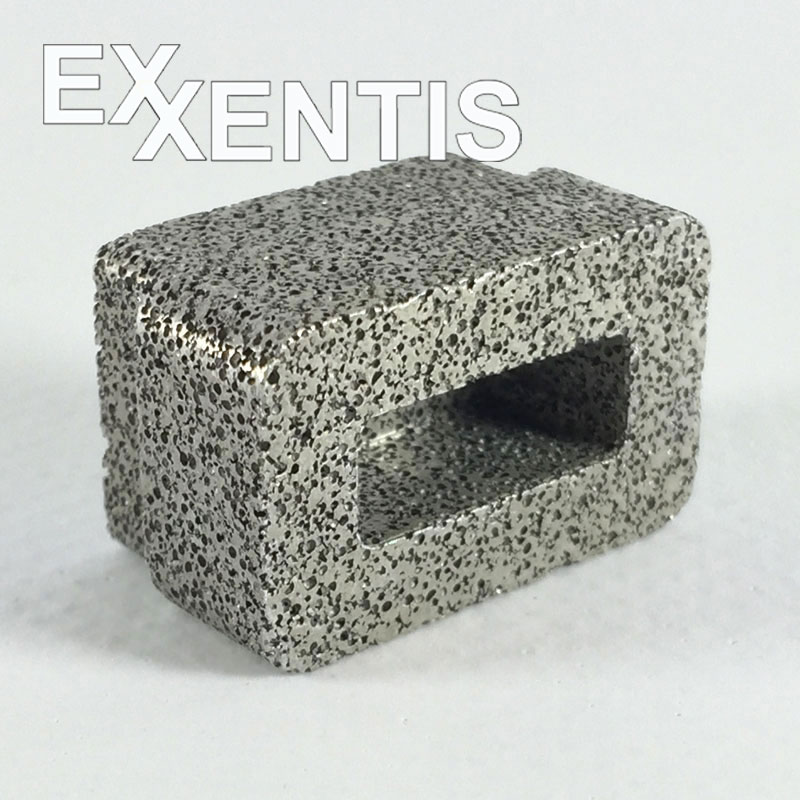

Complex forms

The innovative and relatively simple production technology of porous aluminium results in products of any complexity, shape and dimensions according to customer requirements.

For the production of porous aluminium, liquid aluminium is poured together with granulated salt into a conventional rectangular or cylindrical mould. After cooling of the blank, the material is machined on a lathe, milling machine or CNC machine according to the complexity of the product. By using modern machine tools, we obtain from a rectangular or cylindrical blank products of any complexity and geometry and of high quality. This simple procedure enables us to realize your most innovative ideas.

The uniqueness of this technology gives our customers, among other things, the opportunity to offer not only series production, but also prototypes / individual pieces at attractive prices. For the production of porous aluminium no special / cost-intensive equipment is necessary, e.g. printing forms for the production of sintered products. So you can obtain prototypes of porous aluminium at good conditions, test them and, if necessary, modify, adapt and refine them and test the new model again until the perfect result is available.

The porous aluminium technology makes it possible to vary the material properties by selecting an individual salt combination. For each new project, we will be happy to work with you to define your individual requirements, which not only affect shape and size, but also the desired material properties. Please inform us about your individual requirements, we will be happy to advise you and implement a solution tailored to your requirements.