Production of porous aluminium

Porous aluminium is a porous material that is permeable and permeable over its entire volume. The production of porous aluminium is unique and differs from the production technologies of other porous metals, such as sintered metals or metal foams. The manufacturing process of porous aluminium can be briefly described in three main steps:

1. Aluminium casting with crystal salt

For the production of products from porous aluminium, we do not need cost-intensive press moulds, as is the case with sintering technology, but conventional casting moulds, ingot moulds. The mould is filled with crystal salt, melted aluminium is poured onto it and runs through the salt particles. In order to obtain products with different pore sizes and pore structures, the salt is used in various qualities. All salt grains have contact points with each other, which ensures the permeability of the end product made of porous aluminium.

2. Mechanical post-processing

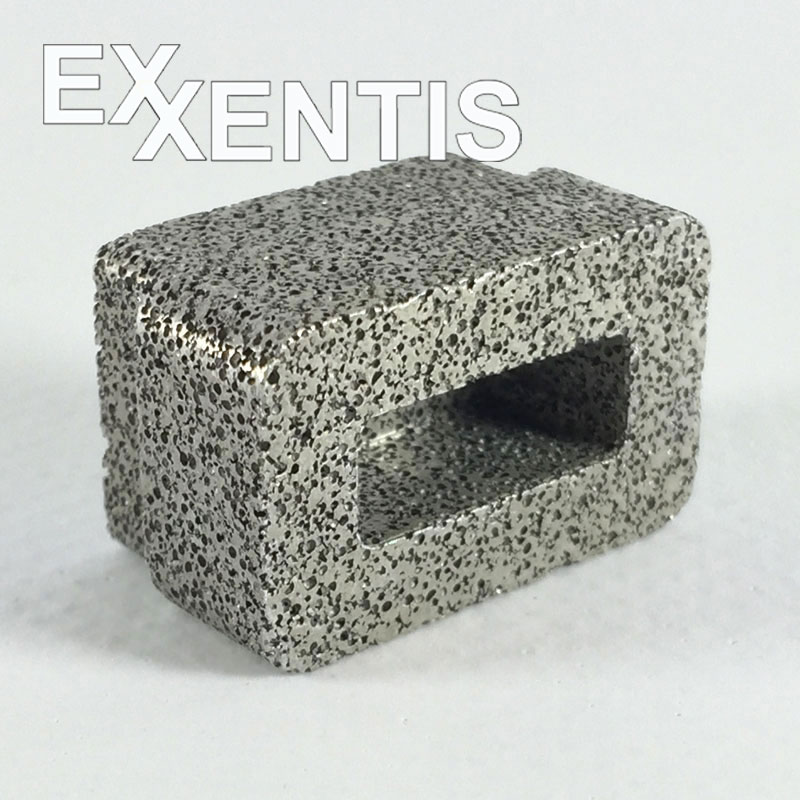

Mechanical post-processing is an important phase in the manufacture of porous aluminium products. The band saw is used to produce blocks and plates in various dimensions and wall thicknesses. The cylindrical products are obtained by turning. Mechanical processing on a milling machine also enables us to realise complex design requests of our customers.

3. Salt washing out

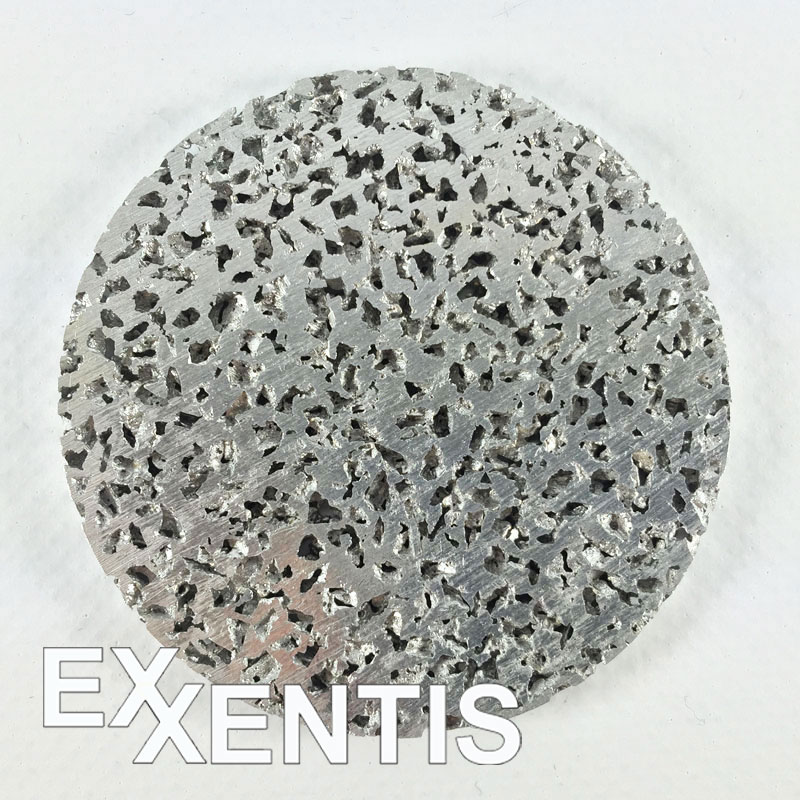

Salt washing is the last main step before the product leaves our production plant. Instead of the salt particles, the pores appear. All pores have an open structure, are connected to each other and therefore the product is completely permeable for liquid and gaseous media.

You receive the product without salt, but can process it mechanically as required. Please contact us, we will be pleased to provide you with recommendations for mechanical processing after salt washing.

Product examples

The innovative and relatively simple manufacturing technology allows us to do this,

to offer an attractive price-performance ratio for prototypes, individual parts and large series.

Not only the salt qualities influence the production of porous aluminium and thus the material properties. There are some casting parameters which can be varied to adjust the quality of the final product. Depending on the application or the customer’s request it makes sense to use one or the other aluminium alloy for the production of porous aluminium. In most cases the AlSi7Mg alloy fits perfectly. There are special cases where e.g. pure aluminium is desired because of the higher heat conduction. We are happy to meet customer requirements and manufacture products from porous aluminium in very different qualities.

It is important to mention that no binder is used in the production of porous aluminium. Porous metals can be produced in different ways. According to a production method, the metal powder is mixed with a binder, e.g. resin. Thanks to the binder, the metal powder sticks together. This reduces the thermal conductivity of the product. There is no binder in the structure of porous aluminium, the thermal conductivity is high.

In the case of cellular metals obtained by sintering technology, the individual metal particles are baked together. The contact points between individual metal beads form resistances for thermal conductivity. Porous aluminium, in contrast to sintered metals, does not consist of individual particles but has a cast structure. The thermal conductivity and strength of porous aluminium products are significantly higher compared to sintered materials.

Mechanical processing is a necessary and indispensable step in the production of porous aluminium. The moulds for this process always have a simple shape, either rectangular or cylindrical. After the blank leaves the mould, it has a layer of solid aluminium on its surface. This layer is removed with the help of mechanical processing so that salt washing is possible at all. For this reason, it is not possible to cast porous aluminium in a mould with a complex geometry (equal to the final shape of the product) such as in the injection moulding process.

When manufacturing porous aluminium products, it is possible to cast other metals into the porous aluminium matrix. This can be interesting for such applications as heat exchange.

As a manufacturer of products made of porous aluminium we have the necessary knowledge to reduce the mechanical processing and to optimize the production costs. This is possible with the help of certain mould inserts. In series production, we develop moulds with specific dimensions and special design. These measures have a direct influence on the final price of the product.

We provide you with the necessary technical advice, which combines your requirements for the product and our manufacturing capabilities. Our engineers are at your side during product development and communicate directly with production management. This approach allows us to continuously develop the manufacturing technology of porous aluminium. The development is based on the customer’s wishes and market requirements and thus always remains up-to-date.